How to Clean Reference Plugs for Reliable Quantum Yield Measurements

Key Points

- Integrating spheres made from sintered PTFE are susceptible to contamination which can greatly alter the results of photoluminescence quantum yield experiments.

- Edinburgh Instruments provide sintered PTFE reference plugs to use when measuring the quantum yield of solid samples.

- This Technical Note explains how to clean these reference plugs by wet-sanding and demonstrates the importance of cleaning them.

- It is recommended that reference pugs are cleaned approximately once per month depending on their level of use and storage conditions.

Introduction

Accurate and repeatable absolute photoluminescence quantum yield (PLQY) measurements require a well-maintained integrating sphere free from contamination. Integrating spheres are made from sintered PTFE which provides high-efficiency, diffuse reflectance across the UV – NIR spectral range (>98% from 270 – 1900 nm). High reflectance, coupled with an integrating sphere’s physical baffle, ensures that light is reflected within the sphere many times. Multiple internal reflections mean that contamination of the surface of the sphere – even that of a small area – can have a large impact on PLQY results.

For these reasons, the user should:

- Always wear gloves when performing PLQY measurements.

- Never touch the integrating sphere surface – even with gloves.

- Always cap samples and ensure their external surfaces are clean and dry.

- Never expose the sphere surface to organic solvents.

While contamination of any part of the internal surface of the sphere is detrimental to PLQY results, it is most important that the first reflection of the focussed excitation beam is on a clean surface. When analysing solid samples using Edinburgh Instruments FS5 and FLS1000 integrating spheres, this first reflection is on a removable sintered PTFE reference plug. Being removable, this reference plug is easy to clean which is important for reliable PLQY measurements.

The Effect of Contaminated Reference Plugs

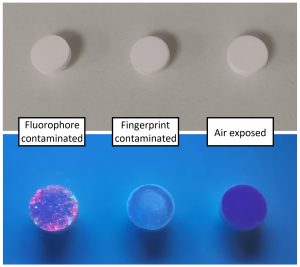

Figure 1. White light-illuminated and UV-illuminated photographs of the reference plugs used before cleaning.

To demonstrate the impact of contamination, PLQY measurements of a high quantum yield phosphor powder were performed using an SC-30 integrating sphere on an Edinburgh Instruments FS5 spectrofluorometer. The same sample emission spectrum was analysed with different reference spectra from three contaminated reference plugs: fluorophore-contaminated; fingerprint-contaminated; and air exposed. The three reference plugs all appear clean under white light; however, when viewed using a UV torch containing a 365 nm LED contamination of two of the reference plugs can be seen (Figure 1).

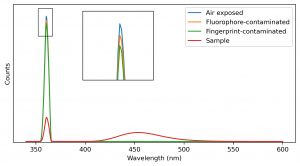

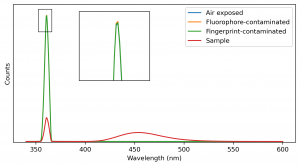

Emission spectra of the three reference plugs and the phosphor powder sample were recorded with identical parameters and can be seen in Figure 2. Using the Fluoracle® quantum yield wizard, the PLQYs calculated were 96.2%, 99.6% and 103.4%, respectively for the air exposed, fluorophore-contaminated, and fingerprint-contaminated reference plugs. All three of these results were higher than the expected PLQY which is ca. 93%.

Figure 2. Emission spectra recorded for PLQY measurements of a phosphor powder using contaminated reference plugs. Inset is a close-up of the scatter peaks for the three reference plugs used.

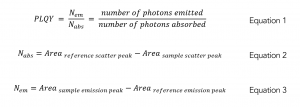

The definition of PLQY is the ratio of the number of emitted photons to the number of absorbed photons. This is shown in Equation 1 where Nem is the number of emitted photons and Nabs is the number of absorbed photons. When the reference plug is contaminated, it can absorb a portion of the excitation light as seen in the inset in Figure 2. This absorption reduces the area under the reference scatter peak meaning that the calculated Nabs is lower than the actual number of photons absorbed by the sample (Equation 2). If this contamination also has an emission, it can increase the area under the emission peak of the reference spectrum. This in turn reduces the calculated Nem (Equation 3).

As seen in the results above, these effects can cause a significant change to the PLQY calculated; with the worst result being a PLQY almost 10% greater than the expected value. Contamination can even result quantum yields calculated to be more than 100% for bright samples.

Cleaning Reference Plugs

Figure 3. UV-illuminated photograph of the reference plugs after being cleaned by wet-sanding.

The reference plugs can be cleaned by lightly sanding them under running water. This wet-sanding removes the thin layer of contamination revealing clean PTFE underneath. It is worth noting that if the reference plug has been exposed to organic solvents, previous contamination can be carried deep within the porous material and cleaning may not be possible. The three reference plugs in this technical note were cleaned using the method below and photographed under UV light (Figure 3).

The method used to clean reference plugs is:

- Place emery cloth (between 240-grit and 800-grit) on a flat surface, such as a cutting board.

- Wearing gloves, and under running water, lightly sand the surface of the reference plug in small circles.

- Continue sanding under running water until the reference plug appears clean under UV light.

- Dry with paper towel (or optical cleaning tissue)

PLQY Measurements with Clean Reference Plugs

Figure 4. Emission spectra of the phosphor powder sample and the reference plugs used for PLQY calculations after cleaning them by wet-sanding. Inset is a close-up of the scatter peaks from the cleaned reference plugs.

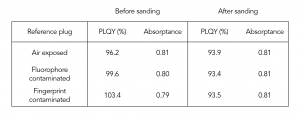

After cleaning the reference plugs, PLQY measurements were performed using the same emission scan parameters as above (Figure 4). The PLQYs for the same sample were now determined to be 93.9%, 93.4%, and 93.5% for the air exposed, fluorophore-contaminated and fingerprint-contaminated reference plugs, respectively. The results of the measurements from before and after cleaning the reference plugs are summarised in Table 1.

Table 1. PLQY results calculated from the same sample using different reference plugs before and after cleaning.

The absorptance values from Table 1, the UV-illuminated photograph in Figure 3, and the scatter peaks inset in Figures 2 and 4, all show that the cleaning process has removed the contamination from the reference plugs. This demonstrates that for accurate PLQY measurements reference plugs should be cleaned regularly; even if the reference plug appears clean under white or UV light. While the effect on PLQY was small for the air exposed reference plug, the result obtained after cleaning was still closer to the expected PLQY of the sample. This is because airborne contaminants such as volatile organic compounds can accumulate on the PTFE surface over time.

Conclusion

Integrating sphere contamination can severely impact PLQY results. This is especially true for the first point of contact of the excitation light. Contamination of this area can result in PLQY results ca. 10% higher than the true value; which can even produce PLQYs greater than 100% for bright samples. This technical note has shown that surface contamination can be removed from reference plugs by wet-sanding with emery cloth. It also demonstrates the importance of regularly cleaning the reference plugs using the method outlined. It is recommended that this cleaning is done approximately once per month depending on the frequency of use and storage conditions of the reference plugs.