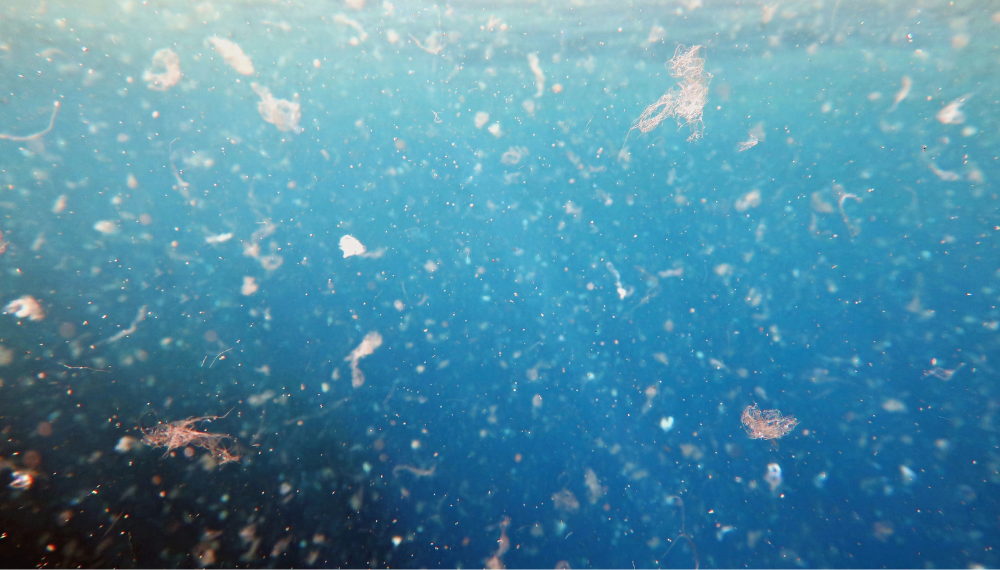

Widespread microplastic pollution has become increasingly concerning because of the detrimental effects that they can have upon living organisms. They are now considered ubiquitous in the natural environment, and various studies report finding microplastics in food products, human organs, and biofluids.1,2

In order to obtain accurate data on the distribution of plastics within the natural environment, testing procedures that enable the size distribution and chemical composition of microplastics to be determined are vital.

Two of the most commonly used techniques in microplastic analysis are FTIR spectroscopy and Raman microscopy. Both methods rapidly provide spectra with high molecular specificity whilst being non-destructive, making them ideal for analysis where sample supply is limited.

FTIR spectroscopy is best suited for fast bulk measurements to identify the chemical structure of polymers present within a sample. Raman microscopy can build upon the information obtained with FTIR by combining data on the chemical identity and morphological characteristics of each individual particle within the sample.

This Application Note demonstrates how both bulk and in-depth analysis can be performed on mixed microplastic samples using the IR5 FTIR Spectrometer and the RM5 Raman Microscope.

The microplastic sample was made by mixing polyethylene (PE) and polytetrafluoroethylene (PTFE) powders purchased from Sigma Aldrich. An IR5 fitted with a Germanium ATR crystal was used for FTIR measurements. An RM5 equipped with a 532 nm laser and a 10X objective was used for the Raman analysis performed on the sample. Both instruments are shown in Figure 1.

Figure 1: A) IR5 FTIR Spectrometer and B) RM5 Raman Microscope.

To analyse the microplastic mixture by FTIR spectroscopy a mixture of PE and PTFE was placed directly onto the ATR crystal and a spectrum was taken. PE is one of the most commonly used and produced plastics in the world, used in a vast array of products from plastic bags to pipes and medical implants. PTFE, also known by the brand name Teflon, is commonly used in cookware production due to its non-stick properties. Their chemical structures are shown in Figure 2.

Figure 2: Chemical structure of PE and PTFE

Figure 3 shows the spectrum of the sample along with the spectra of pure PE and PTFE.

Figure 3: FTIR spectra of the microplastic mix (blue), pure PE (red), and pure PTFE (green).

By comparing the mixture spectrum with sample references, the large peaks that can be seen at 1204 cm-1 and 1150 cm-1 can be attributed to PTFE. The remaining peaks (2916 cm-1, 2847 cm-1, 1469 cm-1 and 719 cm-1) are characteristic of PE.

These results were verified using the KnowItAll® spectral library.3 This software performed a multi-component analysis on the spectrum in order to identify its constituents. KnowItAll analysis confirmed that the obtained spectrum is comprised of peaks attributable to both PE and PTFE.

Whilst FTIR spectroscopy can be used for quick, bulk measurements, Raman microscopy can be used to identify and characterise individual particles to gain insight into the distribution and morphologies of the polymers within the sample. To perform this type of analysis, the ParticleMAP® feature within Ramacle® was used. This tool allows for each individual particle to be highlighted and characterised using Raman spectroscopy.

The mixed microplastic sample on a stainless steel slide was placed under the microscope. Filters were applied within the software to avoid the detection of particles at the edge of the field of view and to ignore particles with an area smaller than 30 µm2. This analysed area is shown below along with the particles that were detected with ParticleMAP (Figure 4).

Figure 4: A) Area of slide chosen for particle analysis and B) particles detected by ParticleMAP.

Once these particles were detected, automatic Raman measurements were carried out on each particle. Of the 30 particles that were detected, 17 were found to be PTFE and the remaining 13 were found to be PE. An example spectrum of each particle type is shown in Figure 5.

Figure 5: Raman spectra of pure PE (red) and PTFE (green).

As well as providing detail on the identity of each of these particles, information on the size of each particle was also obtained during particle detection. This is displayed in Table 1.

Table 1: Polymer type and Area

An understanding of the size of particles within a sample can be vital as particle size can have a significant effect on the particle distribution and movement patterns within aquatic environments as well as the particle’s ability to enter the body and evade filters.4

The detection and characterisation of microplastics is a key aspect of tackling pollution on a global scale. Therefore, any analysis methods must be optimised and refined to provide accurate results swiftly. This Application Note has demonstrated that IR and Raman spectroscopy provide unparalleled analytical power for characterising and studying microplastics, even in complex mixtures. By using both the IR5 FTIR Spectrometer and the RM5 Raman Microscope, bulk measurements and more in-depth and comprehensive particle analysis can be recorded.