Graphene, famously isolated at the University of Manchester in 2004, has since been hailed as a wonder material for its remarkable strength, flexibility, thermal and electrical conductivity. These properties have been applicable across a range of industries from energy to biomedicine.

Now, graphene is being applied well beyond the lab and theoretical experiments, solving an issue much closer to home for many of us in the UK and beyond – repairing potholes.

Road users will be all too familiar with the constant battle against potholes. In the UK, extreme weather and heavy traffic combined with ageing asphalt causes road surfaces to deteriorate and form potholes, costing billions in repairs.

However, a council in North England, just 120 miles from where graphene was first isolated, has been searching for an innovative, long-term solution that would not only repair the roads, but also improve conditions to prevent further damage.

Redcar and Cleveland Borough Council worked with Universal Matter GBR and Tarmac to trial a formulation of asphalt with a graphene-based additive. The resulting roads last longer with less damage over time (including rutting, cracking and of course, potholes). Whilst this new asphalt has been tested in the USA and Canada, the UK application is the first use on a public road.

This is only the beginning; the conductive properties of graphene also allow the potential for “smart” infrastructure. Using sensors, roads could be monitored for strain and performance in real time so preventative repairs could be carried out before any real damage is caused.

Creating such innovations requires the best quality graphene. Characteristics such as structural uniformity, defects and layer thickness will influence the performance of graphene. In this case it would impact on the mechanical stability, heat dissipation and longevity of the road. As technology advances, electrical conductivity will also be affected.

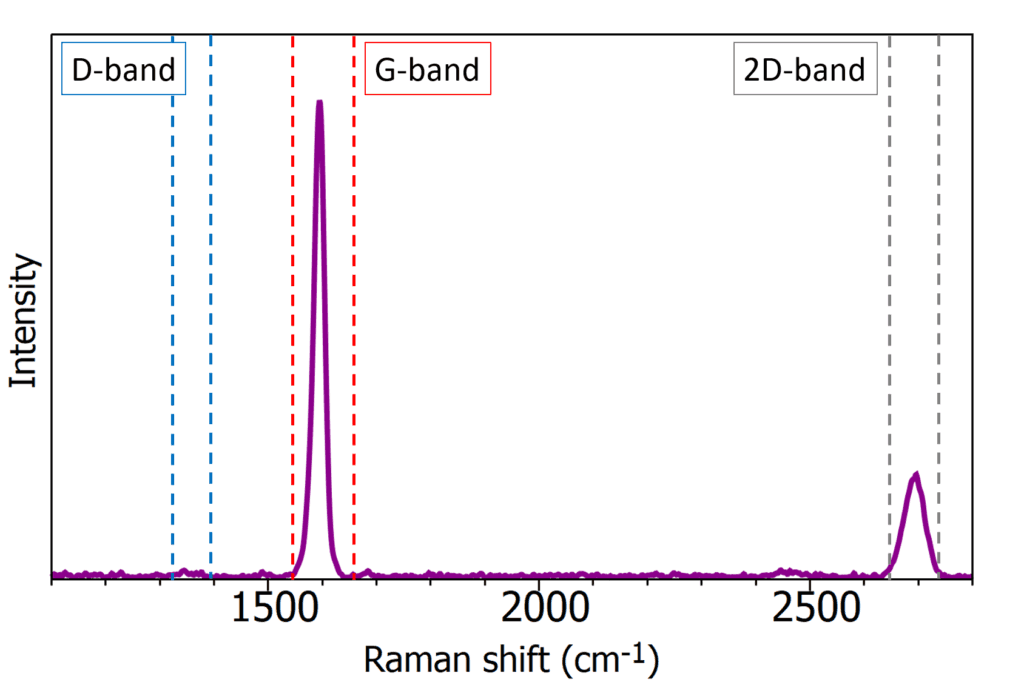

Raman spectroscopy is an excellent technique for characterising graphene.

Graphene’s extraordinary performance in Raman spectroscopy is a direct result of its sp2-bonded carbon lattice. This single-atom-thick hexagonal structure creates a dense network of π-bonds with highly mobile electrons. It is because these electron clouds are easily distorted, or polarisable, by incoming light that graphene produces an exceptionally clear and distinct Raman signal.

In this process, laser-induced vibrations (phonons) cause measurable shifts in the material’s polarisability. Because these vibrations are uniquely sensitive to the number of layers and the presence of defects, Raman spectroscopy serves as the definitive “structural fingerprint” for evaluating graphene’s quality and layer thickness.

Additionally, Raman microscopy is non-destructive so offers high spatial and spectral resolution but requires little to no sample preparation.

If you are interested in learning more about how Raman spectroscopy can be used to characterise graphene, we have lots of application notes and blogs for you:

Raman Microscopy of Graphene – Learn more about how and why Raman microscopy is an excellent technique for characterising graphene.

Raman Mapping of Layer Number and Structural Defects – Discover how Raman Mapping builds a picture of crucial graphene properties such as layer number and strain in this application note.

2D Materials: Future is Flat – Graphene has only been the beginning. Researchers are already studying new classes of 2D materials, such as MXenes. Find out more about them in this blog.

Videos are also available on our YouTube channel:

Graphene Characterisation Using Raman Microscopy: See exactly how easy it is to characterise a graphene sample using Raman microscopy in this virtual demonstration on the RM5 Raman Microscope.