Fluorescence Lifetime Imaging Microscopy (FLIM) is a technique used for characterising the photoluminescent (PL) properties of materials used in LEDs.1 By mapping PL lifetimes across a sample, FLIM provides insight into excited-state dynamics and local environments. This information is essential for understanding and improving LED efficiency and stability.

Defects in III–V semiconductors significantly hinder LED performance by reducing radiative recombination efficiency. FLIM enables direct visualisation of these effects, guiding strategies to mitigate defect-related losses.

III–V semiconductors such as AlInGaP and GaAs alloys are particularly attractive for LEDs due to their tuneable direct bandgaps (Figure 1). These materials enable emission across the visible spectrum while offering superior thermal stability and high device efficiency compared to II–VI or indirect-bandgap semiconductors such as silicon or silicon carbide. AlInGaP/GaAs LED chips, for example, are widely used for high-brightness red, orange, and yellow light emission.

![]()

Figure 1. Direct bandgap of III/V-semiconductors illustrating the tuneability of emission wavelength in LED materials.

To fully exploit the potential of these high-performance materials, advanced characterisation tools are required. In this Application Note, we demonstrate how FLIM can be performed using the Edinburgh Instruments MicroPL upgrade, which can be coupled to the FS5 or FLS1000 PL spectrometers (Figure 2). The technique is used to study the emission properties of LEDs and can help in optimising chip design and understanding factors that limit performance.

Figure 2. MicroPL coupled to an FLS1000 PL Spectrometer for FLIM mapping.

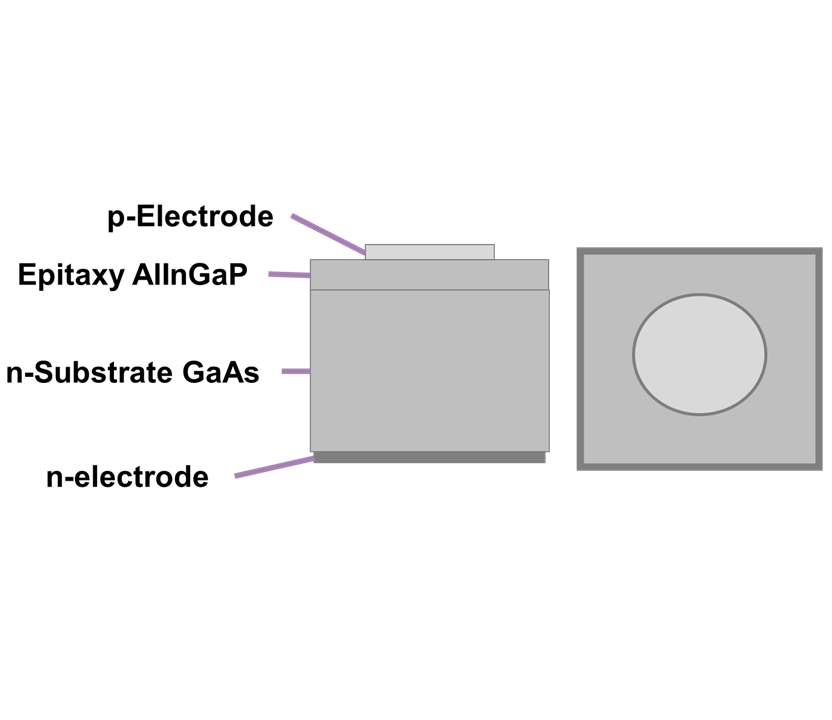

AlInGaP/GaAs visible LED chips were investigated to study the PL properties of the epitaxial AlInGaP layer (Figure 3). The device under study was an orange LED emitting at 610 nm.

Figure 3. Structure of AlInGaP/GaAs LED Chip.

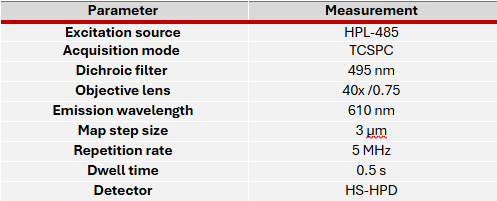

FLIM mapping was performed using the MicroPL upgrade with an FLS1000 spectrometer equipped with a 485 nm pulsed diode laser excitation source and high-speed hybrid photodetector (HS-HPD). PL lifetime measurements were collected using Time-Correlated Single Photon Counting (TCSPC). Full experimental parameters are shown in Table 1.

Table1. Experimental parameters of FLIM mapping

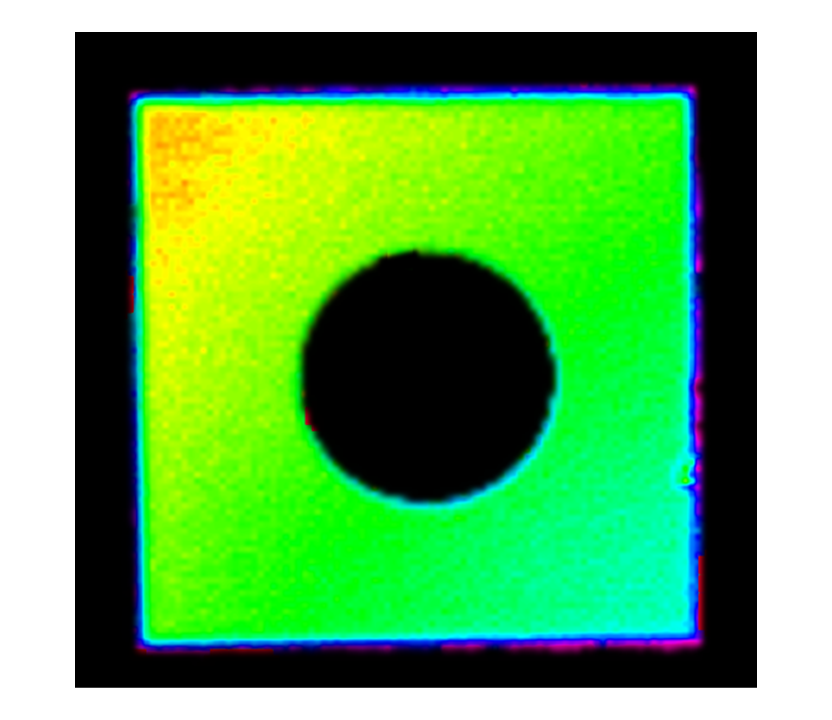

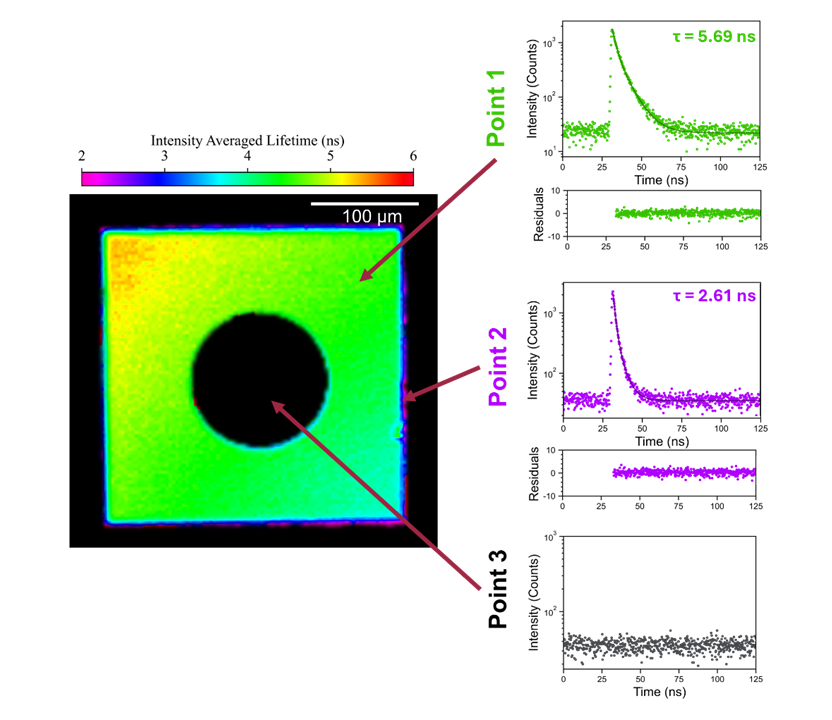

FLIM mapping of the LED chip surface, including the p-electrode and epitaxial AlInGaP layer, revealed spatial variations in lifetime (Figure 4). The results showed that the AlInGaP layer had an average lifetime of around 5.5 ns. It was observed that the lifetime decreased at the edges of the LED chip to around 2.5 ns. In addition, no PL signal was observed at the p-electrode on the chip, which is expected as the electrode material absorbs the excitation and PL light, preventing measurement of the underlying active layer.

Figure 4. FLIM map of AlInGaP/GaAs LED chip showing variation in lifetime across the chip. Inset show PL lifetime at three distinct points of chip – Point 1: Epitaxy AlInGaP, Point 2: Edge of LED and Point 3: p-electrode.

The reduced lifetime at the chip edge is attributed to the sidewall effect, which refers to the performance degradation caused by plasma damage to the LED’s sidewall during the fabrication process.2 These sidewall defects significantly influence device performance, affecting carrier dynamics, light extraction efficiency, and epitaxial layer quality. Optimising sidewall properties, such as angle, smoothness, and etch quality, is therefore critical for achieving high-performance LEDs.

Using FLIM with the MicroPL upgrade for the FLS1000, we mapped the radiative recombination dynamics in AlInGaP/GaAs LEDs. This spatially resolved analysis revealed a significantly reduced carrier lifetime at the chip edges, directly correlating with the sidewall effect. These specific insights derived from FLIM can be used to optimise fabrication processes and chip design, ultimately increasing LED efficiency and accelerating advancements in solid-state lighting and display applications.